ZLD plants

A ZLD treatment system utilizes advanced technological water treatment processes to limit liquid waste at the end of your industrial process to, as the name suggests, zero.

An efficient and well-designed ZLD treatment system should be able to:

•Handle variations in waste contamination and flow

•Allow for required chemical volumes adjustments

•Recover around 95% of your liquid waste for reuse

•Treat and retrieve valuable byproducts from your waste (i.e. salts and brines)

•Produce a dry, solid cake for disposal

Zero Liquid Discharge (ZLD) describes a process that completely eliminates liquid discharge from a system. The goal of any well-designed ZLD system is to minimize the volume of wastewater that requires treatment, process wastewater in an economically feasible manner,while also producing a clean stream suitable for reuse elsewhere in the facility. Interest in Zero Liquid Discharge technology has grown in the industrial manufacturing sector over the past decade.

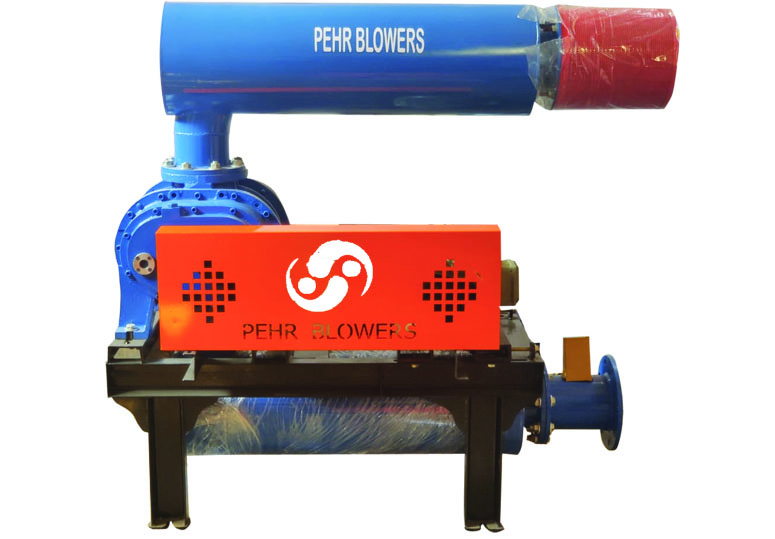

Companies may begin to explore ZLD because of ever tightening wastewater disposal regulations, company mandated green initiative, public perception of industrial impact on the environment, or concern over the quality and quantity of the water supply. The PEHR is providing the turnkey solution for zero liquid discharge, which includes the process like primary treatment, secondary treatment, tertiary treatment and evaporator and dryers. Based on the effluent characteristic’s PEHR will select the process of treatment to recycle 100% water to process.

Features

•Zero Liquid Discharge System which includes Stripper Column, Multi Effect Evaporator and Agitated Thin Film Dryer

•Distillation Column for solvent recovery

•Agitated thin film dryer for drying of product with LOD less than 5%

•Evaporator for concentration of product

•Process design and development