Mechanical vapour Recompressor Evaporators (MVRE)

Mechanical vapor recompression (MVR) is an energy recovery process. It involves taking vapor (usually water vapor) at or a little above, atmospheric pressure and adding energy to it by compression. The result is a smaller volume of vapor, at a higher temperature and pressure, which can be used to do useful work.

Various evaporation techniques are used to concentrate fluids or to achieve Zero Liquid Discharge (ZLD) in wide-ranging industries including dairy, food, pharmaceutical, and chemical, textile, paper etc. Evaporating water from solution is an energy-intensive process. It is often one of the main contributors to a plant’s operating costs

Over the past 10-15 years, Mechanical vapor recompression (MVRE) has become the preferred system in many industries, because of its economy and simplicity of operation. In most instances, the need for steam to provide heat for the evaporation and cooling water for condensing the overhead vapors is virtually eliminated; by installing MVRE. A wide range of turndown is possible in MVRE.

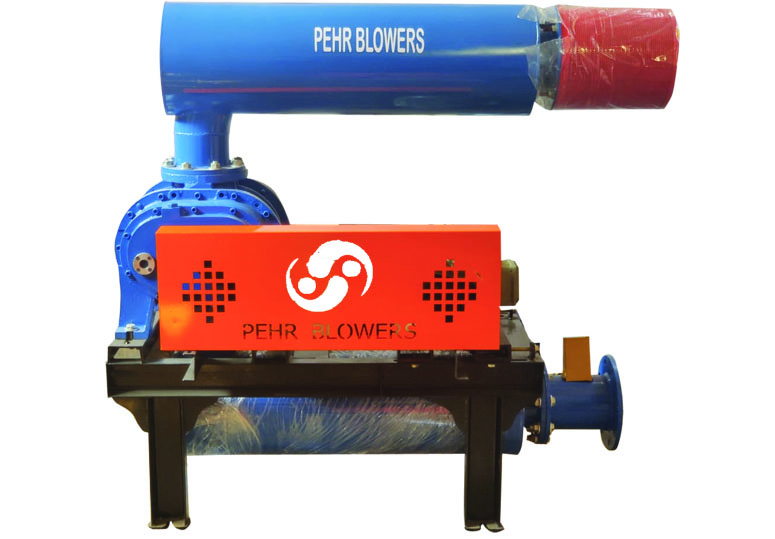

Mechanical Vapor Re-compressor is a system in which the Centrifugal Turbo Fan/Roots Blower is used to recompress the vapors generated by Evaporator at higher pressure using Electrical power. In MVR these same vapors are used again in evaporator as a heating medium. This eliminates the use of fresh steam.

The system operates at a partial vacuum, reducing the boiling temperature and most of the process heat is recovered and recycled within the preheater and evaporator unit. Overall specific energy requirements are dramatically reduced in comparisonto conventional distillation/Evaporation systems

MVR becomes a CHEAPER option as compared to conventional multiple effect evaporators.